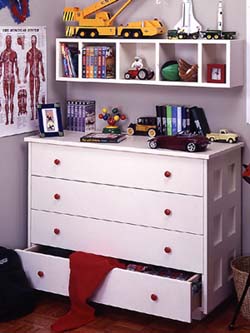

| DRESSER |

| Keep the clothes off the floor

with our easy-to-build dresser. |

| TEXT AND PHOTOS BY NEAL

BARRETT |

|

|

|

While it may seem that some kids can go indefinitely

wearing the same T-shirt and pair of jeans, most have an

appetite for clothes that can strain the most ample

budgets. And where do you put it all?

Well, before you decide to build an addition on the

house, take a close look at our solution. Designed to

match the rest of our bedroom suite, this dresser

features four generous drawers that slide effortlessly

on ball-bearing-equipped tracks, and sturdy plywood

construction with solid poplar detailing.

Best of all, the dresser is easy to build. The case

joinery utilizes a combination of joining plates and

screws–the plates ensure perfect joint alignment while

the screws provide holding power and eliminate the need

for glue and a lot of long clamps. We've also

streamlined drawer construction by employing simple and

fast glue-and-nail joints.

As shown in the photo (right), we've accessorized our

dresser with a wall-mounted storage unit. This piece is

based on the shelf assembly featured with our desk (see

"Stay Tuned"). To build the wall-mounted unit, follow

the instructions given for the desk unit, but eliminate

the leg sections and cut the end panels to 10 1/2 in.

long. | |

|

|

|

Case Construction

Equip your circular saw with a fine-tooth blade to

cut the plywood case parts to size. For accuracy, use a

straightedge guide positioned at the appropriate

distance from your cutline. With the guide square to the

edge of the panel, hold the saw base against the guide

while moving the saw slowly forward.

Use a household iron to apply veneer tape to the

front edges of the plywood case sides, bottom and front

cleat (Photo 1). Set the iron to its highest

setting, and advance it slowly while you press down

firmly. Position the 1 3/16-in.-wide tape so there's a

slight overhang on each side of the panel. |  |

|

| 1--Heat the

hot-melt adhesive on the back of the veneer tape with an

iron. Slowly advance the iron with firm

pressure. | |

|

|

|

Use glue and 6d finish nails to assemble the toe kick

base. Lay the cabinet on its back, and clamp the base to

the case bottom while you bore pilot holes and screw the

toe kick in place (Photo 18).

Set all nailheads and fill the holes with wood

filler. Sand the case and drawer parts, finishing with

180-grit paper, and clean away the dust. Apply a good

latex primer to all cabinet surfaces and drawer faces.

If you wish to finish the drawer boxes, use two coats of

shellac.

When the primer is dry, lightly sand all surfaces

with 180-grit paper. Then dust it off before painting.

Apply two coats of a quality latex semigloss enamel,

following the directions supplied by the manufacturer.

When the paint is dry, reinstall the drawers.

MATERIALS LIST–Dresser

|

| Key |

No. |

Size and description (use) |

| A |

2 |

3/4 x 18 1/8 x 32 5/8" plywood

(side) |

| B |

1 |

3/4 x 18 1/8 x 43 1/2" plywood

(bottom) |

| C |

2 |

3/4 x 4 1/2 x 43 1/2" plywood

(cleat) |

| D |

2 |

3/4 x 3 1/2 x 25 5/8" poplar

(mullion) |

| E |

8 |

3/4 x 3 1/2 x 4 3/8" poplar

(short rail) |

| F |

4 |

3/4 x 3 1/2 x 12 1/4" poplar

(rail) |

| G |

4 |

3/4 x 3 1/2 x 32 5/8" poplar

(stile) |

| H |

1 |

3/4 x 19 1/4 x 46 1/2" plywood

(top) |

| I |

1 |

3/4 x 7/8 x 48" poplar

(edge) |

| J |

2 |

3/4 x 7/8 x 19 1/4" poplar

(edge) |

| K |

8 |

3/4 x 6 3/4 x 18" poplar

(drawer side) |

| L |

4 |

3/4 x 6 3/4 x 41" poplar

(drawer front) |

| M |

4 |

3/4 x 6 1/8 x 41" poplar

(drawer back) |

| N |

4 |

1/4 x 17 1/2 x 41 1/2" plywood

(drawer bottom) |

| O |

4 |

3/4 x 8 x 44 3/4" poplar

(drawer face) |

| P |

1 |

1/4 x 32 5/8 x 45" plywood

(back) |

| Q |

2 |

3/4 x 2 3/4 x 43" poplar (toe

kick face) |

| R |

2 |

3/4 x 2 3/4 x 16" poplar (toe

kick side) |

| S |

3 |

3/4 x 4 x 16" plywood

(cleat) |

| T* |

4 |

18" drawer tracks (Accuride

No. 3037-18") |

| U** |

8 |

1 1/4"-dia. knob (Hafele No.

13893100) |

Misc: No. 20 joining

plates; 2" No. 8 fh woodscrews; 1 1/4" No. 8 fh

woodscrews; 3/4" No. 6 rh woodscrews; 6d finish

nails; 1" brads; birch veneer tape; glue;

sandpaper; latex primer and enamel.

Notes: All

plywood birch veneer; dimensions include veneer

tape where applicable. *Available from Rockler

Woodworking and Hardware, 4365 Willow Dr., Medina,

MN 55340 (stock No. 32821) ** Hafele America Co.,

3901 Cheyenne Dr., P.O. Box 4000, Archdale, NC

27263 | | |

|

| 18--After

assembling the toe kick pieces with glue and nails,

clamp the base to the dresser, bore screwholes and drive

screws. | |

|

|

|